When managing areas exposed to large volumes of water and heavy traffic, having the right drainage system in place is essential. Trench drain channels are an effective solution for these needs. However, selecting the right trench drain channel for heavy loads requires careful consideration of several technical and practical factors. This guide explains how to evaluate materials, load capacities, and design elements to make an informed decision for your project.

Understanding Trench Drain Channels

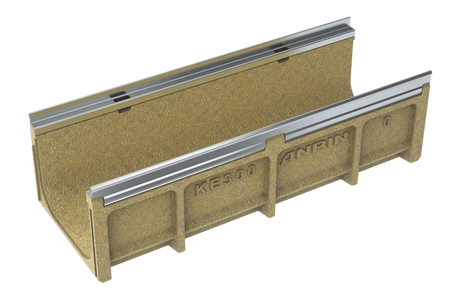

A trench drain channel, also known as a linear drain, is a long and narrow drainage system designed to collect and redirect surface water efficiently. It is commonly installed in places such as industrial zones, loading docks, warehouses, airports, driveways, and parking areas. For heavy-load environments, these systems must not only handle large water volumes but also withstand the stress caused by trucks, forklifts, and machinery.

Trench drains consist of a channel body, gratings, end caps, and outlet connections. Each component contributes to performance and durability. Choosing the right trench drain channel for heavy loads means focusing on both strength and long-term maintenance.

Importance of Choosing the Right Drain for Heavy Loads

Selecting the correct trench drain for heavy loads ensures the safety and longevity of the infrastructure. If an unsuitable system is installed, it can lead to structural damage, water pooling, and costly repairs. A properly chosen drainage system will:

-

Handle expected weight without deformation

-

Resist corrosion and environmental wear

-

Support smooth flow of surface water

-

Require minimal maintenance

-

Enhance site safety and functionality

Determine the Load Class

When deciding how to choose the right trench drain channel for heavy loads, the first step is to understand load classification. Standards such as EN 1433 (Europe) and AASHTO M306 (USA) define load categories ranging from pedestrian to heavy-duty industrial use.

Here’s a simplified guide:

-

Class A–B: Suitable for pedestrian and light vehicle areas.

-

Class C–D: Designed for medium-weight traffic such as cars and small trucks.

-

Class E–F: Built for heavy-duty applications such as industrial plants, airports, and loading docks.

For heavy-load environments, always choose Class E or F trench drain systems to ensure structural stability and long-term performance.

Choose the Right Material

Material selection plays a critical role in how well the trench drain performs under heavy loads. Each material has its advantages and limitations:

1. Polymer Concrete

Known for its high compressive strength and chemical resistance, polymer concrete is ideal for heavy-load drainage applications. It provides smooth flow surfaces and long service life.

2. HDPE (High-Density Polyethylene)

HDPE channels are lightweight, easy to install, and resistant to corrosion. However, they are more suitable for moderate loads rather than extreme industrial applications.

3. Stainless Steel

For industries handling chemicals or food products, stainless steel trench drains are ideal. They offer corrosion resistance, hygiene, and durability, though they can be more expensive.

4. Precast Concrete

Traditional but highly reliable, precast concrete trench drains are perfect for extremely heavy traffic areas such as docks, airports, and highways.

When deciding how to choose the right trench drain channel for heavy loads, always match the material with the load intensity and environment.

Evaluate Grating Options

Gratings cover the top of the trench drain channel and are vital for safety and strength. The right grating ensures the drain performs well while allowing easy access for cleaning.

Common grating materials include:

-

Ductile Iron: Excellent for heavy-duty applications due to its superior load-bearing capacity.

-

Galvanized Steel: Cost-effective and corrosion-resistant, suitable for outdoor areas.

-

Stainless Steel: Used in industries that require hygiene and easy maintenance.

The design also matters — slotted, perforated, or mesh gratings can affect water flow and debris collection. Always ensure the grating complies with the same load class as the trench channel.

Consider Site Conditions and Drainage Flow

Before installation, assess the area’s slope, surface type, and expected water flow. The trench drain must be designed to collect water efficiently and prevent pooling.

-

Slope Configuration: Channels with built-in slope (typically 0.5%–1%) help improve water movement.

-

Inlet and Outlet Design: Proper alignment ensures consistent drainage without clogging.

-

Environmental Factors: Exposure to chemicals, temperature changes, or saltwater can affect material performance.

Matching the system design to site conditions is an essential part of learning how to choose the right trench drain channel for heavy loads.

Focus on Installation and Maintenance

Even the strongest trench drain can fail if not installed correctly. Follow manufacturer guidelines for trench depth, concrete encasement, and alignment. Improper installation can lead to cracking, displacement, or reduced load capacity.

Regular maintenance is also necessary to prevent clogging and structural issues. This includes:

-

Removing debris and sediment periodically

-

Inspecting gratings for damage

-

Checking for cracks or displacement in the channel body

A properly maintained system can last for decades, even under heavy use.

Review Cost vs. Longevity

While it’s tempting to choose the lowest-cost option, drainage systems for heavy loads should be seen as long-term investments. Low-quality materials may lead to frequent replacements and higher repair costs. Instead, focus on overall life-cycle cost — including installation, maintenance, and durability.

Consult with Experts or Manufacturers

If you are uncertain about specifications, consulting with a trench drain manufacturer or civil engineer can save you time and expense. They can help assess your load requirements, suggest suitable materials, and ensure compliance with local standards.

Final Thoughts

Knowing how to choose the right trench drain channel for heavy loads is essential for ensuring a safe, efficient, and durable drainage solution. The correct system protects infrastructure, prevents flooding, and reduces long-term maintenance costs.

To summarize:

-

Understand load classifications

-

Choose durable materials like polymer concrete or ductile iron

-

Match grating strength to channel capacity

-

Consider site-specific conditions

-

Focus on proper installation and regular upkeep

By following these principles, you can confidently select a trench drain channel that will perform effectively for years, even in the most demanding environments.